NDT TESTING SERVICES

Eddy current testing (also commonly seen as eddy current testing and ET) is one of many electromagnetic testing methods used in Non Destructive Testing (NDT) making use of electromagnetic induction to detect and characterize surface and sub-surface flaws in conductive materials.

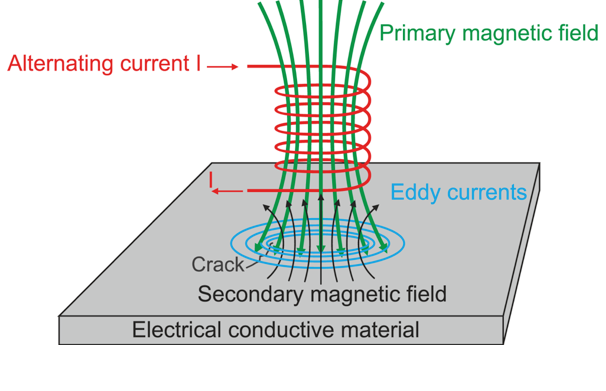

In its most basic form — the single-element ET probe — a coil of conductive wire is excited with an alternating electrical current. This wire coil produces an alternating magnetic field around itself in the direction ascertained by the right-hand rule. The magnetic field oscillates at the same frequency as the current running through the coil. When the coil approaches a conductive material, currents opposed to the ones in the coil are induced in the material — eddy currents.

Variations in the electrical conductivity and magnetic permeability of the test object, and the presence of defects causes a change in eddy current and a corresponding change in phase and amplitude that can be detected by measuring the impedance changes in the coil, which is a tell-tale sign of the presence of defects. This is the basis of standard (pancake coil) ECT.

ET has a very wide range of applications. Because ET is electrical in nature, it is limited to conductive material. There are also physical limits to generating eddy currents and depth of penetration.