NDT TESTING SERVICES

RADIOGRAPHIC TESTING – Industrial radiography is the use of ionizing radiation to view objects in a way that cannot be seen otherwise. Industrial radiography has grown out of engineering, and is a major element of Non Destructive Testing. It is a method of inspecting materials for hidden flaws by using the ability of short wave X-Rays to penetrate various materials.

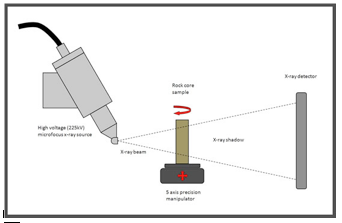

In Radiography Testing the test-part is placed between the radiation source and film. The material density and thickness differences of the test-part will reduce the penetrating radiation through interaction processes involving scattering and/or absorption. The differences in absorption are then recorded on film(s) or through an electronic means. In industrial radiography there are several imaging methods available, techniques to display the final image, i.e. Film Radiography, Real Time Radiography (RTR), Computed Tomography (CT), Digital Radiography (DR), and Computed Radiography (CR).

There are two different radioactive sources available for industrial use; X-ray and Gamma-ray. These radiation sources use higher energy level, i.e. shorter wavelength, versions of the electromagnetic waves. Because of the radioactivity involved in radiography testing, it is of paramount importance to ensure that the Local Rules is strictly adhered during operation.